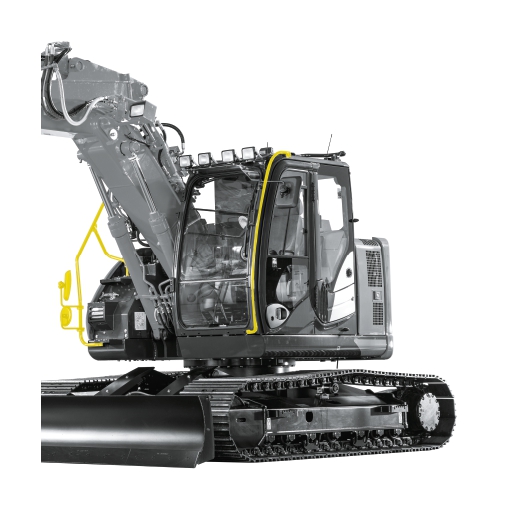

- connecting areas with fracture free forming

- complex 3D Bend

- curvature to match cabin aesthetics

- ready to use

hand rails with complex bends, drilling, end cuts, ready-to-fit assembly as per customer requirement

Designed with safety and ergonomics at the core, Mother India Forming Pvt. Ltd. delivers high-strength, roll-formed hand rails that help OEMs meet international standards for operator protection and fall prevention. Engineered specifically for modern machinery cabins, our components comply with global safety benchmarks for off-highway vehicles and industrial systems.

With rising emphasis on operator safety, properly designed access systems have become mission-critical. According to OSHA (2023), falls account for nearly 35% of all workplace fatalities, highlighting the urgent need for reliable, ergonomically designed hand rails and grab systems. MIF’s roll-formed solutions are built to not only meet these demands but also enhance cabin functionality and structural durability across industries.

🔧 Key Features:

- Fracture-Free Forming: Smooth bends ensure high structural integrity without cracks, even in high-strength steels.

- 3D Multi-Radius Bending: Capable of achieving complex shapes to match modern cabin architecture and safety zones.

- Consistent Aesthetic Curvature: Designed to align with the machine’s cabin profile, improving both function and appearance.

- Ready-to-Install: Delivered with precise holes, end cuts, and optional hinge points to reduce on-site fabrication.

- Material Grades up to 1000 MPa: Formed from ultra-high-strength materials with thicknesses ranging from 0.5 mm to 10 mm.

🚜 Applications:

Our roll-formed hand rails are widely used in:

- Construction Equipment (Excavators, Loaders, Compactors)

- Agricultural Machinery

- Off-Highway Vehicles

- Material Handling and Heavy-Duty Equipment

“Handrails and grab systems are essential in minimizing slip-and-fall risks, especially in off-highway equipment where operators frequently enter and exit elevated cabins.”

— ISO 2867:2011 – Earth-Moving Machinery Access Systems

✅ Why Choose MIF?

With 45+ years of roll forming expertise, MIF provides complete “Concept to Component” solutions backed by in-house tooling, simulation, and machine building capabilities.

“When safety and structure meet precision, efficiency follows. That’s the MIF advantage—high-performance components engineered for reliability and ready for the real world.”

— Santosh V., Director – Sales, Mother India Forming

✔️ Zero-Defect Manufacturing & ISO-Certified Quality

✔️ Made in India, Trusted Globally

✔️ Sustainable Manufacturing with 16,000 sqm Urban Forest & Solar Energy