Some ways Roll Forming can help your industry

May 18, 2023Roll Formed Construction Equipment’s

Enhancing Construction Equipment Efficiency with Roll-Formed Accessory Components

In the construction industry, efficiency and productivity are paramount. To optimize the functionality of construction equipment, accessory components play a crucial role. Among these components, roll-formed accessories such as ladder racks, toolboxes, and steps offer numerous benefits, including durability, versatility, and cost-effectiveness. Let us delve into the advantages of using roll-formed accessory components in construction equipment.

1) Durability and Strength:

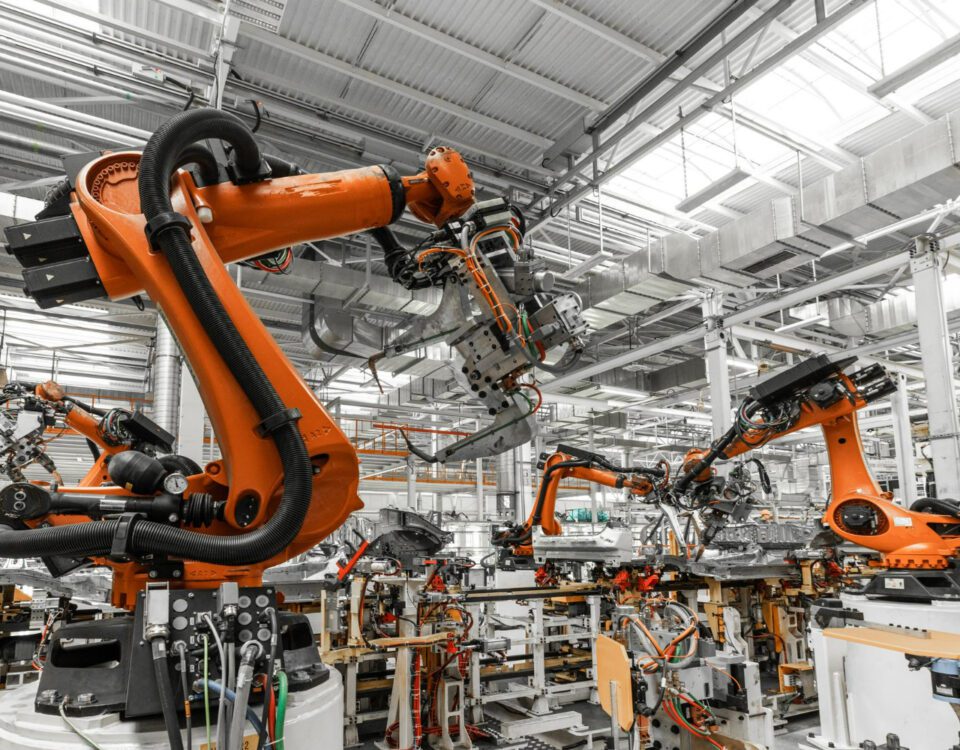

Construction sites can be harsh environments, subjecting equipment to demanding conditions. Roll-formed accessory components are known for their exceptional strength and durability. Manufactured through a process that involves shaping metal strips using a series of roll forming rollers, these components exhibit high structural integrity, ensuring they can withstand heavy loads, vibrations, and impacts. With their robust construction, roll-formed accessories offer long-lasting performance, reducing the need for frequent replacements and increasing overall equipment reliability.

2) Lightweight and Space Optimization:

Weight management is a critical consideration in construction equipment design. Roll-formed accessory components excel in this aspect, as they can be manufactured using lightweight materials without compromising strength. By utilizing lightweight metals like aluminium or high-strength steel, these accessories contribute to reduced overall equipment weight, enhancing fuel efficiency and ease of transport. Moreover, their streamlined designs and compact profiles allow for space optimization, enabling equipment operators to maximize payload capacity and operational efficiency.

3) Versatility and Customization:

Roll-formed accessory components offer immense versatility and can be customized to meet specific equipment requirements. Manufacturers can tailor the dimensions, shapes, and mounting mechanisms of ladder racks, toolboxes, and steps to suit diverse construction equipment models. Customization options also extend to finishes, such as protective coatings or powder coatings, ensuring corrosion resistance and improved aesthetics. This adaptability enables seamless integration of roll-formed accessories with various equipment types, enhancing functionality and operator convenience.

4) Ease of Installation and Maintenance:

Efficiency is essential on construction sites, where time is of the essence. Roll-formed accessory components simplify the installation and maintenance processes, thanks to their design and compatibility features. These accessories often incorporate user-friendly attachment systems, facilitating quick and hassle-free installation without the need for extensive modifications. Furthermore, their robust construction minimizes maintenance requirements, reducing downtime and increasing equipment uptime, thus contributing to optimal productivity.

5) Cost-Effectiveness:

From a financial standpoint, roll-formed accessory components offer notable advantages. Their manufacturing process allows for efficient material usage, minimizing waste and keeping production costs in check. Additionally, their durability and longevity translate into reduced lifecycle costs, as fewer replacements and repairs are required. The lightweight nature of roll-formed accessories also contributes to fuel savings, reducing operational expenses over time. Ultimately, the cost-effectiveness of these components positively impacts the overall profitability of construction equipment owners and operators.

Conclusion:

Roll-formed accessory components such as ladder racks, toolboxes, and steps are indispensable in the construction industry. Offering durability, lightweight construction, versatility, and cost-effectiveness, these components enhance the functionality and efficiency of construction equipment. As the demand for optimized performance continues to rise, the utilization of roll-formed accessories proves to be a valuable investment, empowering construction professionals to tackle their projects with confidence, reliability, and increased productivity.

Mother India Forming Pvt. Ltd. is a leading manufacturer of customized tubular sections and profiles in India. With over 40 years of experience in sheet metal shaping, the company has upgraded its facilities to produce customized roll formed components. Operating from four locations in Bangalore, Mother India Forming specializes in roll forming, bending, laser cutting, and powder coating and caters to industries such as automotive, construction equipment, elevators, racking, safety equipment, textile machinery, and furniture. The company excels in localizing roll-formed components and serves as a global supplier to leading OEMs. With a commitment to quality and technological advancement, Mother India Forming is a trusted partner for providing industry-specific solutions and contributing to the growth of various sectors.